Aluminum extrusions have revolutionized design and manufacturing, offering versatility and reliability across various applications. Aluminum’s natural resistance to corrosion, excellent strength-to-weight ratio, and recyclability further enhance its appeal as a sustainable and efficient material for modern innovation.

Whether building structural components, developing intricate machine parts, or crafting creative architectural designs, aluminum extrusions offer the adaptability to bring bold ideas to life. Learning about the advantages of designing with aluminum extrusions will help you understand why it’s an indispensable resource in our fast-moving, efficiency-driven world.

Lightweight Yet Strong

One of the standout attributes of aluminum extrusions is their remarkable strength-to-weight ratio. Aluminum is a fraction of the weight of other metals such as steel, allowing manufacturers to create robust yet lightweight structures. This feature is beneficial in applications where weight reduction is critical, such as transportation and aerospace. Despite its lightweight nature, aluminum retains sufficient strength to withstand significant stress, making it a reliable choice for demanding environments.

Corrosion Resistance

Durability is critical in any design, and aluminum excels due to its natural corrosion resistance. When exposed to air, aluminum forms a thin oxide layer that protects against degradation. This property makes aluminum extrusions suitable for outdoor applications or environments exposed to moisture, chemicals, or extreme weather conditions. Architects often select aluminum for window frames and other structural elements due to its ability to maintain a pristine appearance while minimizing the need for maintenance.

Design Flexibility and Customization

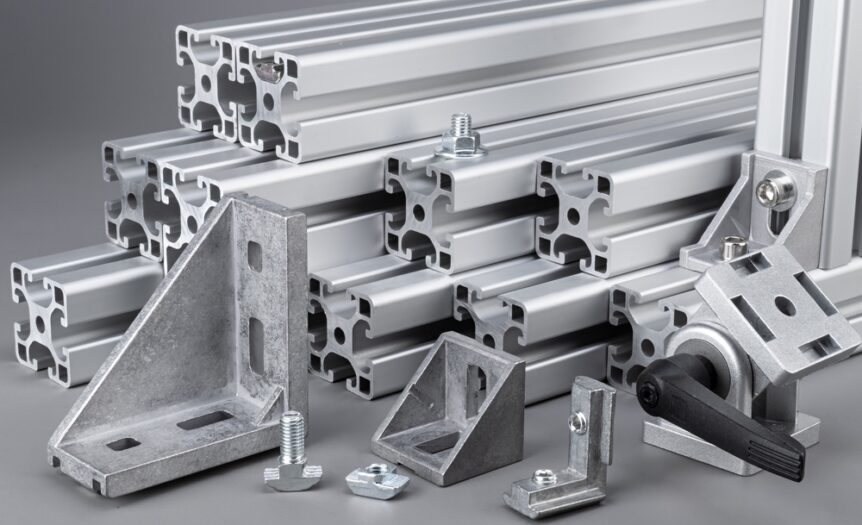

Aluminum extrusions offer unmatched design versatility. The extrusion process allows manufacturers to create intricate shapes and unique profiles, ranging from simple tubes and angles to complex geometries tailored to specific needs. Designers can incorporate multiple functions into a single component, minimizing the need for additional materials. This flexibility enables innovations in product functionality while reducing waste, time, and cost during production. The industries that commonly use aluminum extrusions benefit significantly from this adaptability.

Sustainability

Sustainability is a priority in today’s manufacturing landscape, and aluminum extrusions are an environmentally friendly option. Aluminum is 100% recyclable, making it an excellent choice for reducing the environmental impact of manufacturing processes. Its closed-loop recyclability aligns with greener production practices while satisfying consumer and regulatory demands for sustainable materials.

Cost-Effectiveness

Aluminum extrusions are cost-effective for both small and large-scale projects. Aluminum’s durability reduces the risk of wear and tear, minimizing repair and replacement expenses over the lifespan of a product or structure. Its recyclability enables companies to reuse materials rather than sourcing new ones. These cost advantages make aluminum extrusions a pragmatic choice for businesses looking to optimize their operational budgets.

The advantages of designing with aluminum extrusions go far beyond basic utility. Their lightweight, corrosion-resistant, customizable, and sustainable nature positions them as the leading material in the manufacturing and design industries. Whether applied in construction, automotive engineering, or consumer products, aluminum extrusions empower businesses to enhance their creations while maintaining economic and environmental efficiency.

Deering Estate

Deering Estate

Massage Envy South Miami

Massage Envy South Miami

Calla Blow Dry

Calla Blow Dry

My Derma Clinic

My Derma Clinic

Sushi Maki

Sushi Maki

Sports Grill

Sports Grill

The Healthy Kitchen

The Healthy Kitchen

Golden Rule Seafood

Golden Rule Seafood

Malanga Cuban Café

Malanga Cuban Café

Kathleen Ballard

Kathleen Ballard

Panter, Panter & Sampedro

Panter, Panter & Sampedro

Vintage Liquors

Vintage Liquors

The Dog from Ipanema

The Dog from Ipanema

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Your Pet’s Best

Your Pet’s Best

Indigo Republic

Indigo Republic

ATR Luxury Homes

ATR Luxury Homes

2112 Design Studio

2112 Design Studio

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services

Best Pest Professionals

Best Pest Professionals

HD Tree Services

HD Tree Services

Trinity Air Conditioning Company

Trinity Air Conditioning Company

Cisca Construction & Development

Cisca Construction & Development

Mosquito Joe

Mosquito Joe

Cutler Bay Solar Solutions

Cutler Bay Solar Solutions

Miami Royal Ballet & Dance

Miami Royal Ballet & Dance

Christopher Columbus

Christopher Columbus

Pineview Preschools

Pineview Preschools

Westminster

Westminster

Carrollton

Carrollton

Lil’ Jungle

Lil’ Jungle

Frost Science Museum

Frost Science Museum

Palmer Trinity School

Palmer Trinity School

South Florida Music

South Florida Music

Pinecrest Orthodontics

Pinecrest Orthodontics

Dr. Bob Pediatric Dentist

Dr. Bob Pediatric Dentist

d.pediatrics

d.pediatrics

South Miami Women’s Health

South Miami Women’s Health

The Spot Barbershop

The Spot Barbershop

My Derma Clinic

My Derma Clinic

Miami Dance Project

Miami Dance Project

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Indigo Republic

Indigo Republic

Safes Universe

Safes Universe

Vintage Liquors

Vintage Liquors

Evenings Delight

Evenings Delight

Atchana’s Homegrown Thai

Atchana’s Homegrown Thai

Baptist Health South Florida

Baptist Health South Florida

Laser Eye Center of Miami

Laser Eye Center of Miami

Visiting Angels

Visiting Angels

OpusCare of South Florida

OpusCare of South Florida

Your Pet’s Best

Your Pet’s Best

HD Tree Services

HD Tree Services

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services