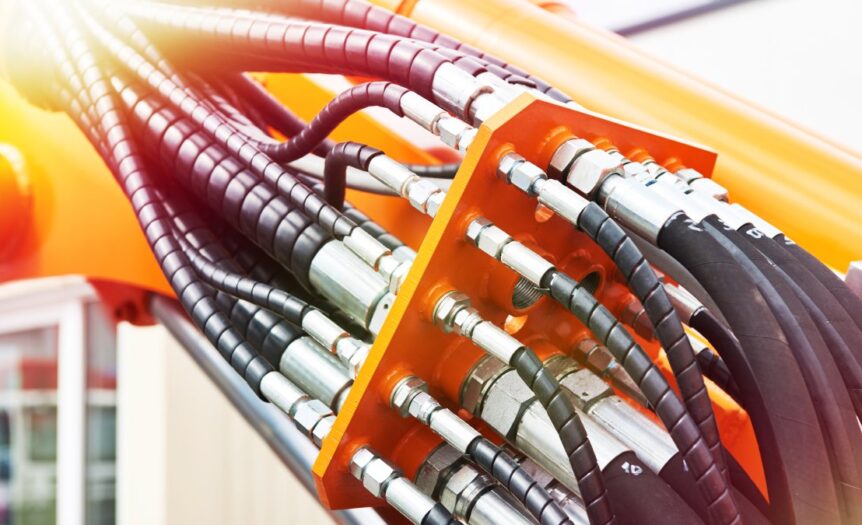

Hydraulic hoses are critical in industrial operations, handling high-pressure flows to keep machinery running smoothly. However, improper installation or neglect in maintenance can result in serious hazards, from equipment damage to workplace accidents. Understanding and applying safety practices is not optional for anyone working with hydraulic systems; it’s essential. Here are practical tips to help you properly install hydraulic hoses and maintain safety on the job.

Select the Right Hydraulic Hose

Choosing the correct hydraulic hose for your specific application is the foundation of safety, so use the STAMPED method to guide your selection. This method evaluates:

- Size

- Temperature

- application

- Material

- Pressure

- Ends

- Delivery

Each of these factors ensures the hose can handle the unique demands of your system. For instance, always confirm the hose’s pressure rating matches or surpasses the system’s requirements. Verify compatibility with the fluid and operating environment to avoid unnecessary deterioration.

Handle and Store Hydraulic Hoses Correctly

Improper handling and storage can damage hydraulic hoses before they even see use. Always transport hoses carefully to avoid kinks, cuts, or abrasions. Keep hoses in a clean, dry space, away from direct sunlight or sharp objects. UV exposure, extreme temperatures, and physical damage can compromise hose integrity, increasing the risk of failure during operation.

Follow Safety Protocols During Installation

Safety starts with using proper equipment and techniques during installation. Wear appropriate personal protective equipment, including gloves and safety glasses. Make sure you secure hoses with clamps or brackets to prevent excessive movement once the system runs. Avoid overtightening fittings, as this can cause cracks or leaks. Lay hoses out without tight bends or curves to reduce stress points and improve their lifespan.

Avoid Common Installation Mistakes

Certain mistakes can jeopardize the safety and effectiveness of hydraulic hoses. Never mix old and new hoses, as inconsistent wear levels can create weak points in the system. Similarly, do not use a hose that is too short to fit comfortably in its application. Insufficient length can increase tension and lead to premature failure. Regularly check for potential hazards, such as improper routing or contact with abrasive surfaces.

Maintain Hoses Regularly for Optimal Safety

Proper maintenance is just as important as correct installation. Regularly inspect hoses for signs of wear, such as cracks, bulges, or leaks. Pay close attention to fittings and connectors, which can become loose due to vibration. Replace hoses at the first sign of damage to avoid more significant issues down the line. Frequent inspections and early replacements can dramatically reduce risks in an industrial environment.

Hydraulic hose safety depends on making the right choices, from proper selection to careful installation and regular maintenance. By implementing these best practices, you can protect personnel, extend equipment life, and prevent costly downtime. Take action today to prioritize hose safety in your operation—your team and machinery will thank you for it.

Deering Estate

Deering Estate

Massage Envy South Miami

Massage Envy South Miami

Calla Blow Dry

Calla Blow Dry

My Derma Clinic

My Derma Clinic

Sushi Maki

Sushi Maki

Sports Grill

Sports Grill

The Healthy Kitchen

The Healthy Kitchen

Golden Rule Seafood

Golden Rule Seafood

Malanga Cuban Café

Malanga Cuban Café

Kathleen Ballard

Kathleen Ballard

Panter, Panter & Sampedro

Panter, Panter & Sampedro

Vintage Liquors

Vintage Liquors

The Dog from Ipanema

The Dog from Ipanema

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Your Pet’s Best

Your Pet’s Best

Indigo Republic

Indigo Republic

ATR Luxury Homes

ATR Luxury Homes

2112 Design Studio

2112 Design Studio

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services

Best Pest Professionals

Best Pest Professionals

HD Tree Services

HD Tree Services

Trinity Air Conditioning Company

Trinity Air Conditioning Company

Cisca Construction & Development

Cisca Construction & Development

Mosquito Joe

Mosquito Joe

Cutler Bay Solar Solutions

Cutler Bay Solar Solutions

Miami Royal Ballet & Dance

Miami Royal Ballet & Dance

Christopher Columbus

Christopher Columbus

Pineview Preschools

Pineview Preschools

Westminster

Westminster

Carrollton

Carrollton

Lil’ Jungle

Lil’ Jungle

Frost Science Museum

Frost Science Museum

Palmer Trinity School

Palmer Trinity School

South Florida Music

South Florida Music

Pinecrest Orthodontics

Pinecrest Orthodontics

Dr. Bob Pediatric Dentist

Dr. Bob Pediatric Dentist

d.pediatrics

d.pediatrics

South Miami Women’s Health

South Miami Women’s Health

The Spot Barbershop

The Spot Barbershop

My Derma Clinic

My Derma Clinic

Miami Dance Project

Miami Dance Project

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Indigo Republic

Indigo Republic

Safes Universe

Safes Universe

Vintage Liquors

Vintage Liquors

Evenings Delight

Evenings Delight

Atchana’s Homegrown Thai

Atchana’s Homegrown Thai

Baptist Health South Florida

Baptist Health South Florida

Laser Eye Center of Miami

Laser Eye Center of Miami

Visiting Angels

Visiting Angels

OpusCare of South Florida

OpusCare of South Florida

Your Pet’s Best

Your Pet’s Best

HD Tree Services

HD Tree Services

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services