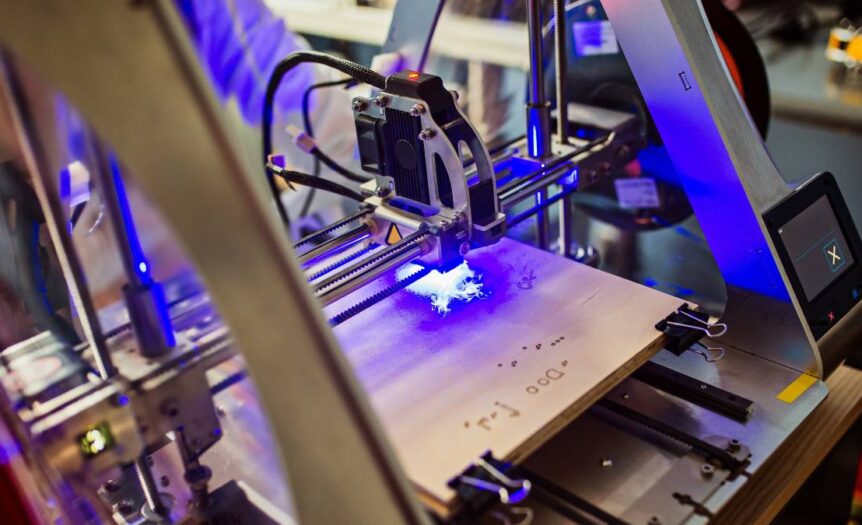

Laser wire marking technology has transformed how industries label and organize wire systems. This innovative method applies permanent, precise, and durable markings that enhance functionality and safety. Companies can improve efficiency and meet strict regulatory requirements with laser marking. Let’s explore the industries that use laser wire marking.

Aerospace Industry

The aerospace industry prioritizes precision and safety, making laser wire marking indispensable. Aircraft rely on complex wiring systems, and accurate wire identification is essential to preventing maintenance errors. Laser markings remain legible even under harsh conditions like extreme temperatures and vibrations. Additionally, manufacturers can integrate laser marking on manufacturing lines to streamline production processes while complying with global aviation standards.

Automotive Industry

The automotive sector uses laser wire marking to improve the reliability and safety of electrical systems. Modern vehicles require intricate wiring for advanced safety features, like sensors and autonomous driving systems, where mislabeling can compromise performance. Laser markings provide long-lasting labels that resist wear and tear, ensuring clear identification even in high-heat engine environments. Using laser marking on production lines, automotive manufacturers can optimize workflows while delivering superior product quality.

Medical Device Industry

The medical device industry depends on laser wire marking for precision and safety. Devices like pacemakers, surgical equipment, and diagnostic tools require marked wires to facilitate proper assembly and reduce the risk of malfunction. Laser-marked wires adhere to stringent health regulations by ensuring accurate tracking and traceability.

Telecommunications Industry

Telecommunications companies use laser wire marking to produce durable, high-speed data and fiber optic cables. These cables power everything from internet connections to critical communication infrastructure. Laser markings make identifying and organizing cable networks easier, particularly in large-scale installations. The markings are highly resistant to environmental factors like UV radiation, ensuring reliable outdoor performance.

Laser wire marking continues to shape the future of the above industries. Its ability to deliver precise, readable, and lasting markings ensures safety, improves efficiency, and meets strict compliance standards. Companies adopting this technology on their manufacturing lines set the stage for more reliable and innovative products.

Deering Estate

Deering Estate

Massage Envy South Miami

Massage Envy South Miami

Calla Blow Dry

Calla Blow Dry

My Derma Clinic

My Derma Clinic

Sushi Maki

Sushi Maki

Sports Grill

Sports Grill

The Healthy Kitchen

The Healthy Kitchen

Golden Rule Seafood

Golden Rule Seafood

Malanga Cuban Café

Malanga Cuban Café

Kathleen Ballard

Kathleen Ballard

Panter, Panter & Sampedro

Panter, Panter & Sampedro

Vintage Liquors

Vintage Liquors

The Dog from Ipanema

The Dog from Ipanema

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Your Pet’s Best

Your Pet’s Best

Indigo Republic

Indigo Republic

ATR Luxury Homes

ATR Luxury Homes

2112 Design Studio

2112 Design Studio

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services

Best Pest Professionals

Best Pest Professionals

HD Tree Services

HD Tree Services

Trinity Air Conditioning Company

Trinity Air Conditioning Company

Cisca Construction & Development

Cisca Construction & Development

Mosquito Joe

Mosquito Joe

Cutler Bay Solar Solutions

Cutler Bay Solar Solutions

Miami Royal Ballet & Dance

Miami Royal Ballet & Dance

Christopher Columbus

Christopher Columbus

Pineview Preschools

Pineview Preschools

Westminster

Westminster

Carrollton

Carrollton

Lil’ Jungle

Lil’ Jungle

Frost Science Museum

Frost Science Museum

Palmer Trinity School

Palmer Trinity School

South Florida Music

South Florida Music

Pinecrest Orthodontics

Pinecrest Orthodontics

Dr. Bob Pediatric Dentist

Dr. Bob Pediatric Dentist

d.pediatrics

d.pediatrics

South Miami Women’s Health

South Miami Women’s Health

The Spot Barbershop

The Spot Barbershop

My Derma Clinic

My Derma Clinic

Miami Dance Project

Miami Dance Project

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Indigo Republic

Indigo Republic

Safes Universe

Safes Universe

Vintage Liquors

Vintage Liquors

Evenings Delight

Evenings Delight

Atchana’s Homegrown Thai

Atchana’s Homegrown Thai

Baptist Health South Florida

Baptist Health South Florida

Laser Eye Center of Miami

Laser Eye Center of Miami

Visiting Angels

Visiting Angels

OpusCare of South Florida

OpusCare of South Florida

Your Pet’s Best

Your Pet’s Best

HD Tree Services

HD Tree Services

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services