Metal manufacturing is a vital industry that produces a wide range of products we use daily, from planes and cars to household appliances and electronics. However, this industry also generates significant material waste, which has economic and environmental impacts.

Let’s explore five ways to reduce material waste in metal manufacturing so that businesses can be more efficient, sustainable, and profitable.

Embrace Lean Manufacturing Principles

Lean manufacturing systematically reduces waste by optimizing production processes, minimizing inventory levels, and eliminating non-value-adding activities. By adopting lean principles in metal manufacturing, you can reduce material waste. You only produce what is necessary when needed. To implement lean manufacturing, you must identify and eliminate unnecessary steps, processes, or inventory items that add no value to the end product. This approach ensures you use resources more efficiently and minimize the scrap created.

Recycle Metal Scraps

Collecting and recycling scraps is another way to reduce material waste in metal manufacturing. Metal scraps come out during production, and if you don’t manage them properly, they can accumulate quickly, taking up valuable space and increasing costs. Recycling metal scraps reduces the amount of raw materials necessary for manufacturing, lowers energy consumption and greenhouse gas emissions, and saves money on disposal costs.

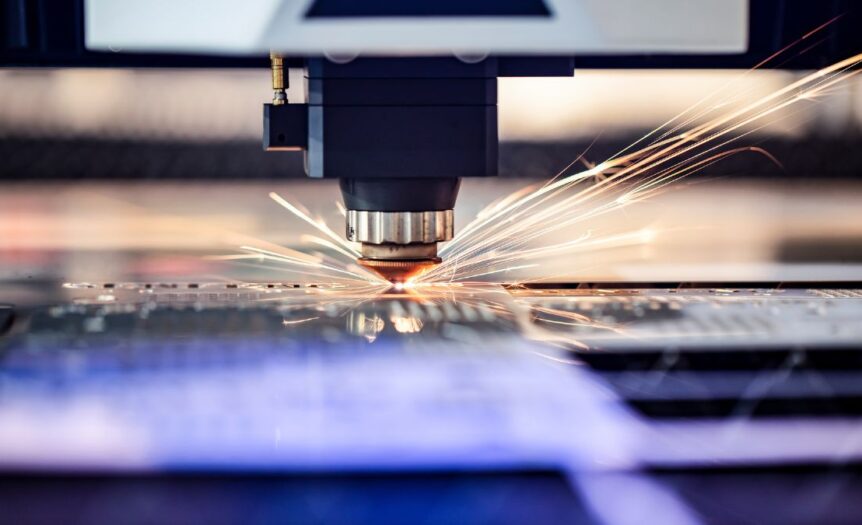

Update Your Equipment

Outdated equipment can produce lots of material waste when working with metals. Newer machines and tools are more precise and efficient, and they can reduce the amount of scrap metal produced by up to 50 percent. Adding newer machines can give lots of different benefits and add value. Knowing how something like a laser cutting machine adds value to metal fabrication can help you decide the best investment.

Implement Smart Materials Management

Smart material management involves planning and controlling material flow, storage, and transportation to minimize waste and maximize efficiency. By implementing smart material management practices, you can ensure that the right materials arrive at the right time and in the right quantity. This approach can help prevent overstocking, understocking, and material waste due to mishandling or damage during transportation.

Collaborate With Suppliers

Suppliers play a critical role in the metal manufacturing process. Collaborating with your suppliers can help reduce material waste by ensuring that they provide materials that meet your quality standards in the necessary amount. It also ensures they deliver them on time. Additionally, you can work with your suppliers to identify opportunities to improve your processes that can reduce waste and costs.

Reducing material waste is essential for maintaining sustainable and profitable operations in metal manufacturing. Implementing the above strategies can reduce material waste and create a more sustainable and efficient manufacturing process. Doing this will save money on raw materials, energy, and disposal costs while reducing your environmental impact.

Deering Estate

Deering Estate

Massage Envy South Miami

Massage Envy South Miami

Calla Blow Dry

Calla Blow Dry

My Derma Clinic

My Derma Clinic

Sushi Maki

Sushi Maki

Sports Grill

Sports Grill

The Healthy Kitchen

The Healthy Kitchen

Golden Rule Seafood

Golden Rule Seafood

Malanga Cuban Café

Malanga Cuban Café

Kathleen Ballard

Kathleen Ballard

Panter, Panter & Sampedro

Panter, Panter & Sampedro

Vintage Liquors

Vintage Liquors

The Dog from Ipanema

The Dog from Ipanema

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Your Pet’s Best

Your Pet’s Best

Indigo Republic

Indigo Republic

ATR Luxury Homes

ATR Luxury Homes

2112 Design Studio

2112 Design Studio

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services

Best Pest Professionals

Best Pest Professionals

HD Tree Services

HD Tree Services

Trinity Air Conditioning Company

Trinity Air Conditioning Company

Cisca Construction & Development

Cisca Construction & Development

Mosquito Joe

Mosquito Joe

Cutler Bay Solar Solutions

Cutler Bay Solar Solutions

Miami Royal Ballet & Dance

Miami Royal Ballet & Dance

Christopher Columbus

Christopher Columbus

Pineview Preschools

Pineview Preschools

Westminster

Westminster

Carrollton

Carrollton

Lil’ Jungle

Lil’ Jungle

Frost Science Museum

Frost Science Museum

Palmer Trinity School

Palmer Trinity School

South Florida Music

South Florida Music

Pinecrest Orthodontics

Pinecrest Orthodontics

Dr. Bob Pediatric Dentist

Dr. Bob Pediatric Dentist

d.pediatrics

d.pediatrics

South Miami Women’s Health

South Miami Women’s Health

The Spot Barbershop

The Spot Barbershop

My Derma Clinic

My Derma Clinic

Miami Dance Project

Miami Dance Project

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Indigo Republic

Indigo Republic

Safes Universe

Safes Universe

Vintage Liquors

Vintage Liquors

Evenings Delight

Evenings Delight

Atchana’s Homegrown Thai

Atchana’s Homegrown Thai

Baptist Health South Florida

Baptist Health South Florida

Laser Eye Center of Miami

Laser Eye Center of Miami

Visiting Angels

Visiting Angels

OpusCare of South Florida

OpusCare of South Florida

Your Pet’s Best

Your Pet’s Best

HD Tree Services

HD Tree Services

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services