The injection molding process not only benefits the industries it serves but the consumers as well, as various products are made using this process, from household items to service tools. To gain a deeper appreciation for this process, let’s dive into what goods come from the injection molding process and how everyday consumers benefit.

How Injection Molding Works

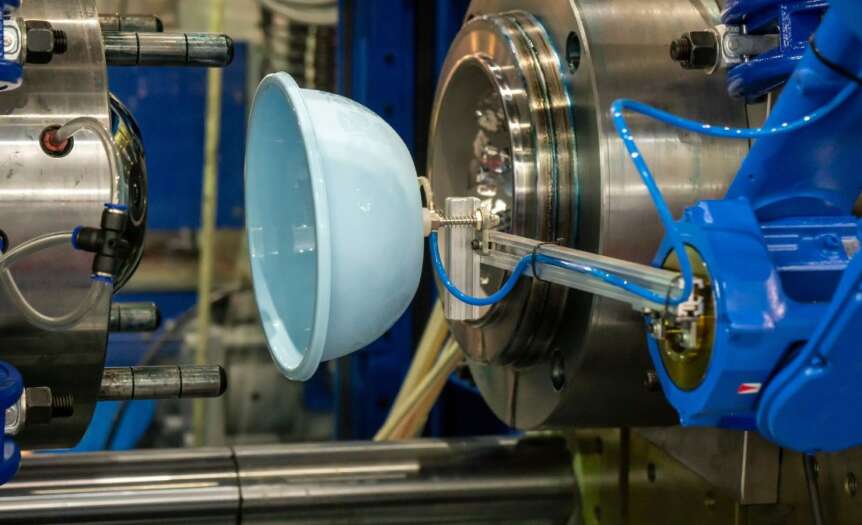

The primary goal of injection molding is to create a large number of parts in a timely fashion. The product engineers design a mold that will form the pieces and parts set out by the manufacturer. Plastic material is injected into the mold for a set amount of time at the right temperature to create the part. This process is incredibly versatile for various industries because of how many molds and parts benefit from this method.

Common Products That Benefit from Injection Molding

The list of products that benefit from injection molding is vast. But some of the most common items are found in everyday consumers’ homes and lives. Here are a few of the most commonly used products that injection molding is responsible for.

Consumer Goods

Various consumer goods come to the market thanks to injection molding techniques. But the most common can be found in the home, including:

- Toothbrushes

- Kitchen utensils

- Caps and lids

- Toilet seats

Sporting Goods

Another relatively common industry that benefits from injection molding is the sporting goods industry. Things like helmets, mouth guards, and cleat forms are all products of injection molding. Additionally, manufacturers can request specific types of plastics for molding to produce durable protective gear for athlete safety.

Medical Industry

The healthcare industry benefits greatly from injection molding processes. The devices and instruments used in various medical applications are unique to the field. Injection molding for medical devices allows manufacturers to get specific about materials and create a high volume of products.

A few products that benefit include:

- Syringes

- Beakers and test tubes

- Implants

- Surgical devices

Industrial Parts

One unique thing about injection molding is how reliable the process is with various materials. The oil and gas industry requires specific types of materials to decrease degradation and increase safety. Thanks to injection molding, they can request durable, high-capacity matter for parts production.

Another industrial application that benefits from injection molding is auto manufacturing. Components like mirror casings, door panels, and interior buttons are all mass-produced through injection molding.

When it comes to injection molding, the results of the process are all around us. Whether you’re a consumer, engineer, or surgeon, almost none of the items you use would be available without this unique parts manufacturing method.

Deering Estate

Deering Estate

Massage Envy South Miami

Massage Envy South Miami

Calla Blow Dry

Calla Blow Dry

My Derma Clinic

My Derma Clinic

Sushi Maki

Sushi Maki

Sports Grill

Sports Grill

The Healthy Kitchen

The Healthy Kitchen

Golden Rule Seafood

Golden Rule Seafood

Malanga Cuban Café

Malanga Cuban Café

Kathleen Ballard

Kathleen Ballard

Panter, Panter & Sampedro

Panter, Panter & Sampedro

Vintage Liquors

Vintage Liquors

The Dog from Ipanema

The Dog from Ipanema

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Your Pet’s Best

Your Pet’s Best

Indigo Republic

Indigo Republic

ATR Luxury Homes

ATR Luxury Homes

2112 Design Studio

2112 Design Studio

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services

Best Pest Professionals

Best Pest Professionals

HD Tree Services

HD Tree Services

Trinity Air Conditioning Company

Trinity Air Conditioning Company

Cisca Construction & Development

Cisca Construction & Development

Mosquito Joe

Mosquito Joe

Cutler Bay Solar Solutions

Cutler Bay Solar Solutions

Miami Royal Ballet & Dance

Miami Royal Ballet & Dance

Christopher Columbus

Christopher Columbus

Pineview Preschools

Pineview Preschools

Westminster

Westminster

Carrollton

Carrollton

Lil’ Jungle

Lil’ Jungle

Frost Science Museum

Frost Science Museum

Palmer Trinity School

Palmer Trinity School

South Florida Music

South Florida Music

Pinecrest Orthodontics

Pinecrest Orthodontics

Dr. Bob Pediatric Dentist

Dr. Bob Pediatric Dentist

d.pediatrics

d.pediatrics

South Miami Women’s Health

South Miami Women’s Health

The Spot Barbershop

The Spot Barbershop

My Derma Clinic

My Derma Clinic

Miami Dance Project

Miami Dance Project

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Indigo Republic

Indigo Republic

Safes Universe

Safes Universe

Vintage Liquors

Vintage Liquors

Evenings Delight

Evenings Delight

Atchana’s Homegrown Thai

Atchana’s Homegrown Thai

Baptist Health South Florida

Baptist Health South Florida

Laser Eye Center of Miami

Laser Eye Center of Miami

Visiting Angels

Visiting Angels

OpusCare of South Florida

OpusCare of South Florida

Your Pet’s Best

Your Pet’s Best

HD Tree Services

HD Tree Services

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services