Warehousing is an essential industry. But it’s also a dangerous one. Warehouses are notorious for having a devastatingly high injury rate, and it’s easy to guess why. Warehouse workers spend their days reaching, bending, lifting, and performing other arduous and dangerous activities that can cause strain and injury.

But what if we told you that warehouses don’t have to be inherently perilous? Improving warehouse ergonomics can dramatically reduce the likelihood of on-the-job injuries by making strenuous jobs less strenuous. Here are some ways to improve warehouse ergonomics and keep your hard-working employees out of harm’s way.

Reduce Package Handling

The packages and loads that warehouse workers carry around come in various sizes, shapes, and materials. A small package won’t do too much damage, but a large one can leave a worker with an aching back. For this reason, OSHA recommends that humans shouldn’t lift more than 50 pounds on the regular.

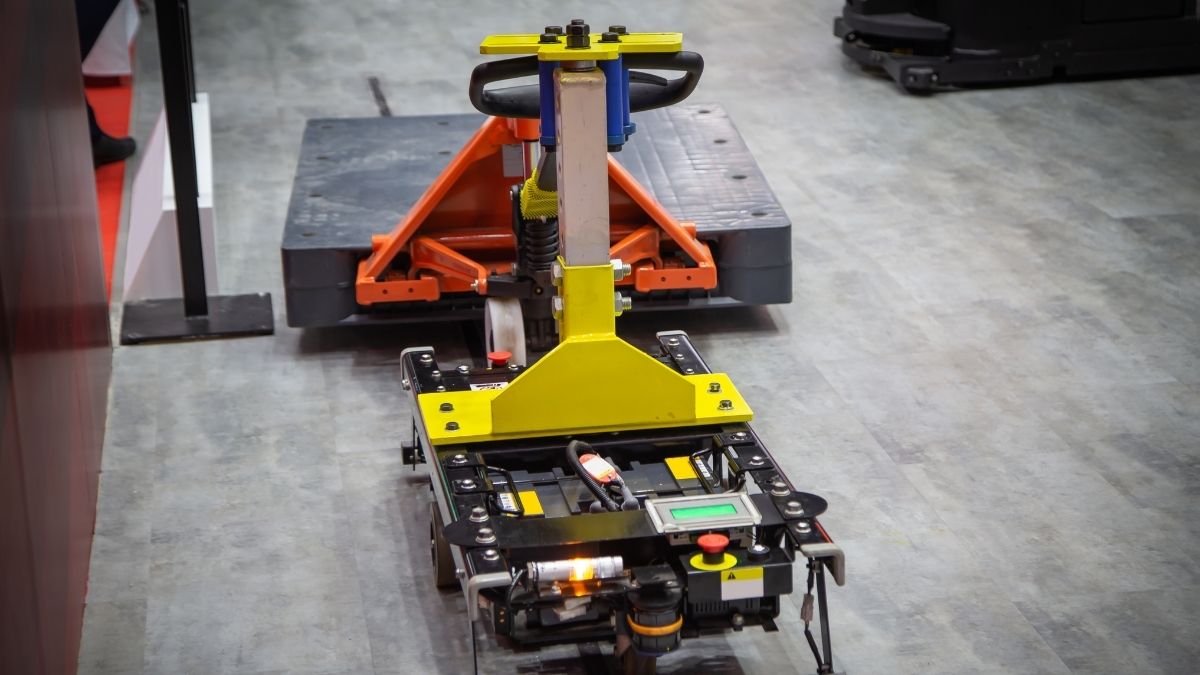

But what should you do if you have to move something that’s 50 pounds or heavier? You have two options. You can have multiple people move the load (which lessens the likelihood of injury but doesn’t eliminate it) or have a machine move it (it’s pretty hard to injure something that’s metal). LGVs (laser-guided vehicles) are a great option for warehouses that need to handle heavier-than-normal loads. AGVs, which are LGVs with fewer awesome lasers, are also an option.

Enforce Breaks

The next way to improve warehouse ergonomics is to enforce breaks. A lot of them. You’re already providing your employees with the one to three breaks a day required by law. But since warehousing is hard and back-breaking work, it doesn’t hurt to give your employees a few extra five-minute rest periods sprinkled throughout their shift.

These short breaks give your employees the chance to rejuvenate their aching muscles. They can close their eyes for a few minutes to reduce eye strain. Or, they could do some stretches to improve blood circulation and lower their risk of muscle cramps and stiffness.

Keep Machines at Waist Level

Remember how your parents would always tell you to not slouch? That’s because slouching places excess strain on your muscles, ligaments, and tendons, and can even shift the vertebrae of your spine out of alignment. Conversely, overextending your limbs can result in dislocated muscles and tendons and even serious nerve damage.

If the machines in your warehouse are too short or too high, your employees will be forced to bend down or stand on their tiptoes to use them. The solution is to ensure all machines are placed at waist level. But unless your employees miraculously share the same height, “waist level” means something different for everyone. How do you choose the best height for your machines, then? By consulting an ergonomics expert, of course!

Deering Estate

Deering Estate

Massage Envy South Miami

Massage Envy South Miami

Calla Blow Dry

Calla Blow Dry

My Derma Clinic

My Derma Clinic

Sushi Maki

Sushi Maki

Sports Grill

Sports Grill

The Healthy Kitchen

The Healthy Kitchen

Golden Rule Seafood

Golden Rule Seafood

Malanga Cuban Café

Malanga Cuban Café

Kathleen Ballard

Kathleen Ballard

Panter, Panter & Sampedro

Panter, Panter & Sampedro

Vintage Liquors

Vintage Liquors

The Dog from Ipanema

The Dog from Ipanema

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Your Pet’s Best

Your Pet’s Best

Indigo Republic

Indigo Republic

ATR Luxury Homes

ATR Luxury Homes

2112 Design Studio

2112 Design Studio

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services

Best Pest Professionals

Best Pest Professionals

HD Tree Services

HD Tree Services

Trinity Air Conditioning Company

Trinity Air Conditioning Company

Cisca Construction & Development

Cisca Construction & Development

Mosquito Joe

Mosquito Joe

Cutler Bay Solar Solutions

Cutler Bay Solar Solutions

Miami Royal Ballet & Dance

Miami Royal Ballet & Dance

Christopher Columbus

Christopher Columbus

Pineview Preschools

Pineview Preschools

Westminster

Westminster

Carrollton

Carrollton

Lil’ Jungle

Lil’ Jungle

Frost Science Museum

Frost Science Museum

Palmer Trinity School

Palmer Trinity School

South Florida Music

South Florida Music

Pinecrest Orthodontics

Pinecrest Orthodontics

Dr. Bob Pediatric Dentist

Dr. Bob Pediatric Dentist

d.pediatrics

d.pediatrics

South Miami Women’s Health

South Miami Women’s Health

The Spot Barbershop

The Spot Barbershop

My Derma Clinic

My Derma Clinic

Miami Dance Project

Miami Dance Project

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Indigo Republic

Indigo Republic

Safes Universe

Safes Universe

Vintage Liquors

Vintage Liquors

Evenings Delight

Evenings Delight

Atchana’s Homegrown Thai

Atchana’s Homegrown Thai

Baptist Health South Florida

Baptist Health South Florida

Laser Eye Center of Miami

Laser Eye Center of Miami

Visiting Angels

Visiting Angels

OpusCare of South Florida

OpusCare of South Florida

Your Pet’s Best

Your Pet’s Best

HD Tree Services

HD Tree Services

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services