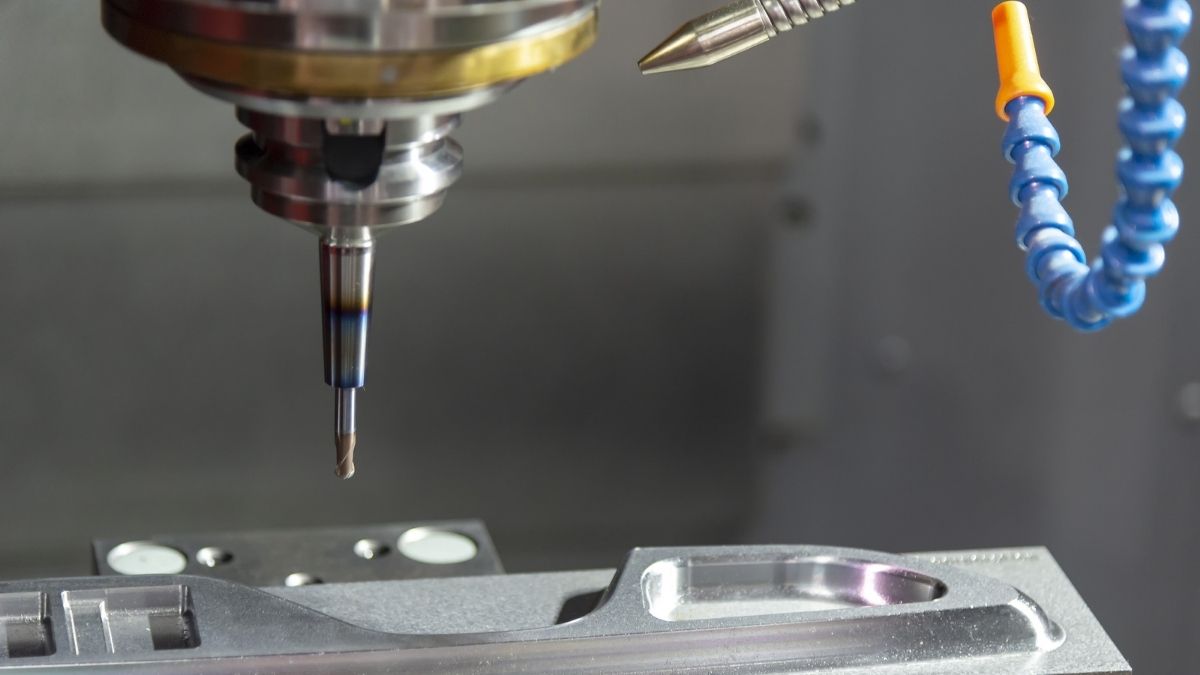

Sheet metal fabrication is great for when manufacturers need to create durable parts for industrial and high-impact applications. However, certain factors can drive up the costs of the process and put a strain on a budget. To learn about a few effective ways to cut sheet metal fabrication costs and keep your project within your budget, continue reading.

Simplify the Design

Unlike other part production processes such as reaction injection molding, sheet metal fabrication is not well suited to producing complex, intricate parts. To create parts with a more sophisticated design, you’ll need to implement secondary processes. These processes increase the amount of time it takes to produce a sheet metal product and also greatly hike up the price. If you’re looking for ways to cut sheet metal fabrication costs, sticking to a simpler product design can help you achieve your goal.

Choose Materials Wisely

One of the many benefits of the sheet metal fabrication process is the wide range of material options that you can choose from, such as stainless steel, aluminum, and copper. When creating a part, make sure to use this variety of choices to your advantage. If you’re looking to keep costs low, you may not want to opt for high-cost stainless steel—especially if your application does not require such a high-quality material. Instead, consider using low-cost aluminum to create your part. Opting for a cheaper material is especially beneficial if you’re prototyping and don’t need to meet the high-quality standards of a final product.

Be Mindful of Your Part’s Bend Radius

The bend radius for your sheet metal parts can have a big impact on their overall cost. To save money, try to consider a manufacturer’s standard tooling when designing your part’s geometry. Since most shops will already have tools designed for certain specifications, they won’t have to spend extra money on a specialized toolset to achieve the necessary bend radius. As a result, you can minimize the overall production cost of your parts.

Deering Estate

Deering Estate

Massage Envy South Miami

Massage Envy South Miami

Calla Blow Dry

Calla Blow Dry

My Derma Clinic

My Derma Clinic

Sushi Maki

Sushi Maki

Sports Grill

Sports Grill

The Healthy Kitchen

The Healthy Kitchen

Golden Rule Seafood

Golden Rule Seafood

Malanga Cuban Café

Malanga Cuban Café

Kathleen Ballard

Kathleen Ballard

Panter, Panter & Sampedro

Panter, Panter & Sampedro

Vintage Liquors

Vintage Liquors

The Dog from Ipanema

The Dog from Ipanema

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Your Pet’s Best

Your Pet’s Best

Indigo Republic

Indigo Republic

ATR Luxury Homes

ATR Luxury Homes

2112 Design Studio

2112 Design Studio

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services

Best Pest Professionals

Best Pest Professionals

HD Tree Services

HD Tree Services

Trinity Air Conditioning Company

Trinity Air Conditioning Company

Cisca Construction & Development

Cisca Construction & Development

Mosquito Joe

Mosquito Joe

Cutler Bay Solar Solutions

Cutler Bay Solar Solutions

Miami Royal Ballet & Dance

Miami Royal Ballet & Dance

Christopher Columbus

Christopher Columbus

Pineview Preschools

Pineview Preschools

Westminster

Westminster

Carrollton

Carrollton

Lil’ Jungle

Lil’ Jungle

Frost Science Museum

Frost Science Museum

Palmer Trinity School

Palmer Trinity School

South Florida Music

South Florida Music

Pinecrest Orthodontics

Pinecrest Orthodontics

Dr. Bob Pediatric Dentist

Dr. Bob Pediatric Dentist

d.pediatrics

d.pediatrics

South Miami Women’s Health

South Miami Women’s Health

The Spot Barbershop

The Spot Barbershop

My Derma Clinic

My Derma Clinic

Miami Dance Project

Miami Dance Project

Rubinstein Family Chiropractic

Rubinstein Family Chiropractic

Indigo Republic

Indigo Republic

Safes Universe

Safes Universe

Vintage Liquors

Vintage Liquors

Evenings Delight

Evenings Delight

Atchana’s Homegrown Thai

Atchana’s Homegrown Thai

Baptist Health South Florida

Baptist Health South Florida

Laser Eye Center of Miami

Laser Eye Center of Miami

Visiting Angels

Visiting Angels

OpusCare of South Florida

OpusCare of South Florida

Your Pet’s Best

Your Pet’s Best

HD Tree Services

HD Tree Services

Hamilton Fox & Company

Hamilton Fox & Company

Creative Design Services

Creative Design Services